SkyClean is a high impact, carbon-negative technology developed by Stiesdal Fuel Technologies

The SkyClean technology combines biofuel production and carbon capture and storage. It is an integrated solution to three major climate change challenges on a global scale:

- The need for significantly reduced greenhouse emissions from agriculture

- The need for capture and sequestration of atmospheric carbon

- The need for carbon-neutral fuels for transportation

How SkyClean works

The core of SkyClean is a pyrolysis process in which organic waste from agriculture and for-estry is converted into biochar, gas, and oil by heating to a high temperature without the pres-ence of oxygen.

Dry plant material typically contains approximately 50% carbon that the plants have extracted from the atmosphere in the form of CO2. All the carbon in waste from agriculture and forestry thus also comes from the atmosphere. This applies regardless of whether the waste is purely plant-based or whether it is waste from livestock or the food industry.

In the pyrolysis process, half of the carbon in the waste is converted to biochar, while the other half becomes oil and gas. Biochar is a stable material that only decomposes very slowly, and the half of the carbon that turns into biochar is effectively removed from the atmosphere.

The half of the carbon that does not turn into biochar comes out of the pyrolysis process as gas and oil. The gas can be used as fuel in the heat supply and in industry, and the oil can be refined into fuel for the transport sector.

The fuel production aspect of SkyClean adds very valuable revenue streams, in the essence funding the carbon capture and storage.

Low-cost and effective carbon capture

Unlike conventional carbon capture (CCS) where the emission of fossil carbon is avoided by carbon capture from flue gas, SkyClean carbon capture does not just avoid emissions, it re-moves CO2 from the atmosphere.

Among the wide variety of current and proposed carbon capture and storage (CCS) technolo-gies, biochar production from sustainable biomass has several advantages:

- It is by far the cheapest CCS technology.

- It actively integrates with and boosts local economies.

- It supports sustainable growth in the farming sector.

The industrialization approach

Stiesdal Fuel Technologies is developing SkyClean plants with standardized modules for feedstock storage and preparation, pyrolysis, post-processing of oil and gas, and post-processing of biochar.

The SkyClean process has been tested with a large number of trials on a 200-kW plant set up at Risø Campus, Danish Technical University (DTU).

A 2 MW intermediate stage pilot plant with full automation is scheduled for 2021. Here, all stages of the overall process will be tested and optimized before the establishment of a 20MW demo plant, ready for construction in 2022.

In a Danish context, SkyClean has the potential to provide a reduction of 12 million tons CO2 equivalent for Denmark.

SkyClean’s role in cleaning up the atmosphere

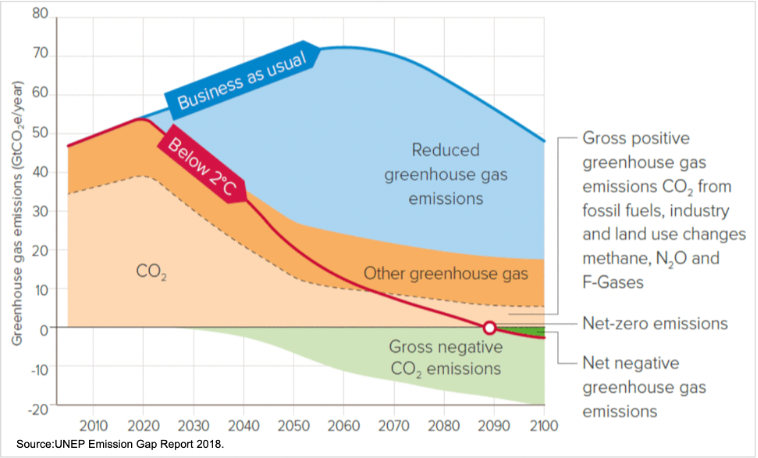

At Stiesdal, we are committed to contributing to climate change mitigation and to help humanity avoid catastrophic effects of climate change. The SkyClean technology is one our most important contributions, since we know that it is not enough to cut emissions. We also need to remove some of the excessive carbon from the atmosphere. Consequently, we need large-scale application of carbon-negative technologies like SkyClean and many others.

The minimum amount of CO2 that will need to be removed from the atmosphere, in order not to breach the maximum allowance of atmospheric CO2 specified by IPCC, will be on the order of 10 gigatons or more per year from 2055 onwards.

A number of large economies have committed to become carbon-neutral within a few decades – China by 2060, the EU by 2050, and California by 2045. Given that there will always be una-voidable CO2 emissions, these commitments are inherently assuming large-scale CO2 cap-ture through carbon negative technologies.

Among carbon negative technologies, atmospheric clean-up through biochar sequestration stands out as a safe, cost-effective, and technologically feasible solution.

With its industrialized, relatively low-tech scalable approach, the SkyClean technology represents a climate mitigation technology with high impact available for both developed and developing economies.