At Stiesdal Hydrogen we have taken up the challenge to speed up the development of affordable green hydrogen.

The HydroGen Electrolyzer is a 3 MW unit for pressurerized hydrogen production at low cost.

The HydroGen technology represents a full system industrialization approach where not just the unit itself but also the installation process and Balance of Plant is highly industrialized.

Designed for the next generation green hydrogen plant

The HydroGen technology is based on a rethinking of traditional hydrogen electrolyzers, transitioning from a chemical industry design approach to a design that integrates seamlessly with renewable energy sources.

This approach supports the expansion of next-generation green hydrogen plants, aligning with global efforts to decarbonize hard-to-abate sectors.

Unique features of the HydroGen Electrolyzer

- A modular system arrangement designed for mass production by established industrial partners and suppliers with a global footprint.

- A self-contained system suitable for easy transportation and outdoor installation, requiring no buildings.

- Minimal Balance-of-Plant requirements with plug-and-play installation.

- A unique pressure vessel concept enabling high hydrogen delivery pressure without compression losses.

- Dynamic operation capability, allowing the system to follow volatile electricity spot prices, ultimately following stand-alone wind and solar PV output.

HydroGen’s dynamic range performance

The green hydrogen of the future should be produced with wind and solar, hence the need for a system that can be a flexible consumer of electricity. HydroGen’s active frontend is prepared for a future where hydrogen production plays a significant role on the demand side of electricity markets.

Technical specifications

| Rated power | 3100 kW |

| Delivery pressure | Up to 35 bar |

| Hydrogen production nominal | Up to 59 kg H2 per hour |

| Hydrogen purity (wet basis) | Higher than 99,7% |

| System efficiency (AC) | 78% |

| Start-up time | Under 5 minutes |

| Dynamic range | 25-100% |

| Dynamic ramp-up rate | 1% load per second |

Full system industrialization

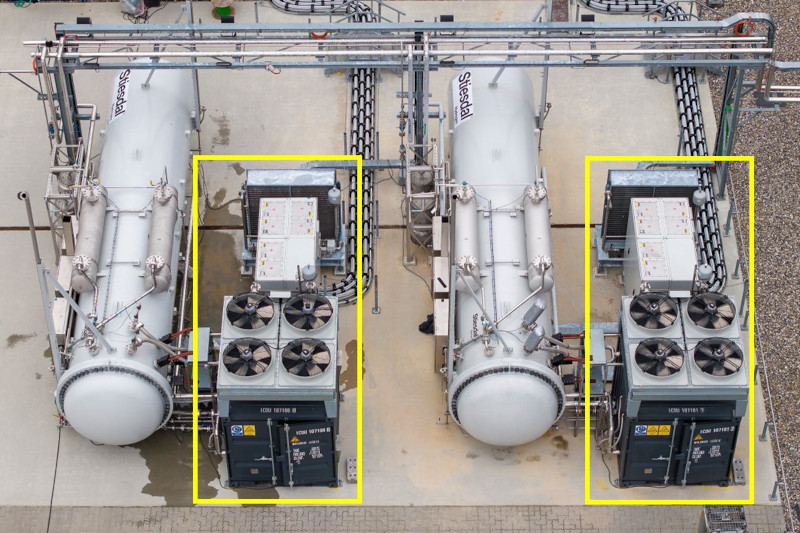

The HydroGen Electrolyzer is from the outset designed for plug & play installation. This includes a full system industrialization approach where not just the unit itself but also the installation process and Balance of Plant is highly industrialized.

The entire electrolyzer system is supplied on two trucks. Once delivered to site, the installation process of the unit is limited to mounting of the modules on pre-installed point foundations, and mechanical and electrical completion at well-defined interfaces.

The Balance of Plant is reduced to a minimum, with no requirements for buildings or large support systems.

Supply chain centered design strategy

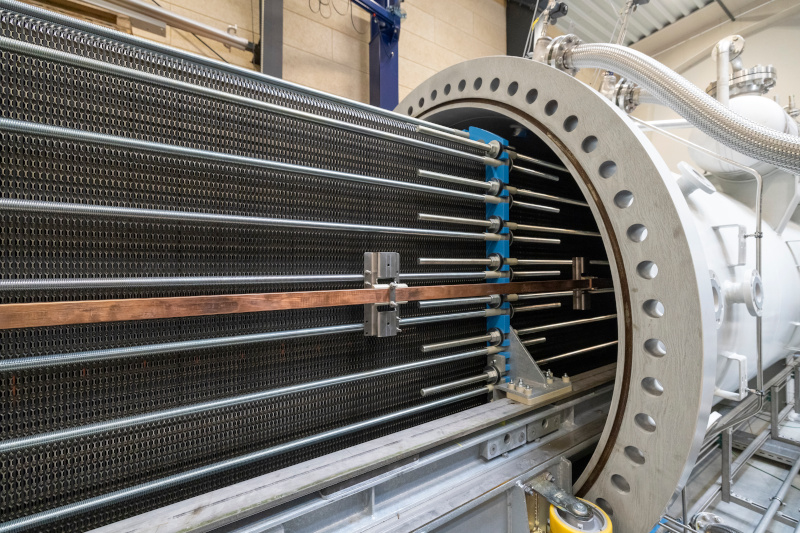

Stiesdal Hydrogen has opted for a supply chain-centered design strategy of the electrolyzer, where the system’s main components are adapted to the mass production methodologies applied by established industrial partners with a global footprint. The main components are standardized and modularized in a manner similar to that applied by other large-volume industrial products, e.g. as applied in the truck manufacturing sector.

Why alkaline

The HydroGen Electrolyzer is based on conventional alkaline electrolysis. The alkaline technology uses electrodes made with abundant elements and does not require the noble metal catalysts required for other electrolysis technologies. It operates at low temperature, ensuring a long system lifetime. The relative simplicity of alkaline electrolysis is highly compatible with mass production and use of standard industrial technologies.